IYINI UDABA?

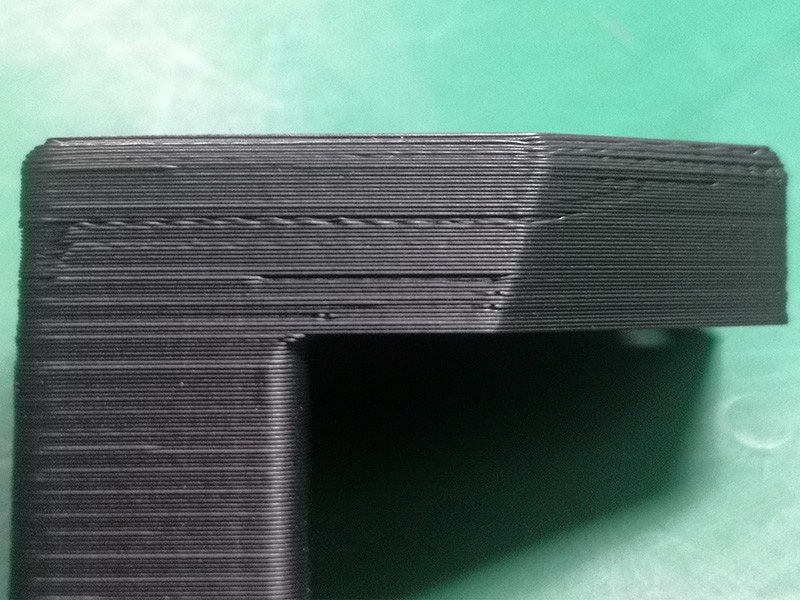

Ukuphrinta okuhle kudinga ukukhishwa okuqhubekayo kwe-filament, ikakhulukazi izingxenye ezinembile.Uma i-extrusion ihlukahluka, izothinta ikhwalithi yokugcina yokuphrinta efana nezindawo ezingavamile.

IZIMBANGELA EZINGASEKHO

∙ I-Filament Ibhajwe noma Iphithene

∙ Imbobo Eminyene

∙ Ukugaya I-Filament

∙ Ukusetha Isofthiwe Okungalungile

∙ I-Filament Endala noma Eshibhile

∙ Izinkinga ze-Extruder

AMACEBISO OKUXOXA INKINGA

I-Filament Inamathele noma Iphikisiwe

I-filament kufanele ihambe ibanga elide ukusuka ku-spool kuya emlonyeni, njenge-extruder kanye neshubhu yokudla.Uma i-filament ibhajwe noma iphithane, i-extrusion izoba ngokungahambisani.

KHIPHA I-Filament

Hlola ukuthi i-filament ibambekile noma ihlangene, futhi uqinisekise ukuthi i-spool iyakwazi ukujikeleza ngokukhululekile ukuze i-filament ikhululeke kalula ku-spool ngaphandle kokumelana kakhulu.

SEBENZISA UKUHLUKA KWESIXESHA

Uma i-filament ilinyazwe kahle ku-spool, iyakwazi ukuqaqa kalula futhi mancane amathuba okuba iphingane.

HLOLA ITHUBU LOKUDLA

Kumaphrinta we-Bowden drive, i-filament kufanele ihanjiswe ngeshubhu yokudla.Hlola ukuze uqiniseke ukuthi i-filament ingahamba kalula ngeshubhu ngaphandle kokumelana kakhulu.Uma kukhona ukumelana okukhulu eshubhuni, zama ukuhlanza ishubhu noma ukugcoba okuthile.Futhi hlola ukuthi ububanzi be-tube bufanele yini i-filament.Okukhulu noma okuncane kakhulu kungaholela kumphumela omubi wokuphrinta.

I-Nozzle Jammed

Uma i-nozzle iboshwe ngokwengxenye, i-filament ngeke ikwazi ukuphuma ngokushelelayo futhi ingaguquki.

Iya kuI-Nozzle Jammedukuze uthole imininingwane eyengeziwe yokuxazulula le nkinga.

Gukuhlanza i-Filament

I-Extruder isebenzisa igiya lokushayela ukuphakela imicu.Nokho, igiya linzima ukulibamba emculweni wokugaya, ukuze umcu onzima uphume ngokuqhubekayo.

Iya kuUkugaya i-Filamentukuze uthole imininingwane eyengeziwe yokuxazulula le nkinga.

IUkusetha Isofthiwe elungile

Izilungiselelo zesofthiwe yokusika zilawula i-extruder kanye nozzle.Uma ukulungiselelwa kungafaneleki, kuzothinta ikhwalithi yokuphrinta.

ukuphakama kwesendlalelo SETTING

Uma ukuphakama kwesendlalelo kusetha kuncane kakhulu, isibonelo 0.01mm.Khona-ke kukhona indawo encane kakhulu yokuthi i-filament iphume ku-nozzle futhi i-extrusion izoba ngokungahambisani.Zama ukusetha ubude obufanele obufana no-0.1mm ukuze ubone ukuthi inkinga iyahamba yini.

Ububanzi be-extrusion SETTING

Uma isethingi yobubanzi be-extrusion ingaphansi kakhulu kobubanzi bombhobho, isibonelo ububanzi be-extrusion obungu-0.2mm bomlomo ongu-0.4mm, i-extruder ngeke ikwazi ukusunduza ukugeleza okungaguquki kwefilament.Njengomthetho ojwayelekile wesithupha, ububanzi be-extrusion kufanele bube phakathi kuka-100-150% we-diameter ye-nozzle.

I-Filament endala noma eshibhile

Imicu emidala ingase imunce umswakama emoyeni noma yonakale ngokuhamba kwesikhathi.Lokhu kuzobangela ikhwalithi yokuphrinta ukuthi yehlise isithunzi.I-filament yekhwalithi ephansi ingase iqukathe izithasiselo ezengeziwe ezithinta ukuvumelana kwe-filament.

SHINTSHA IFILAMENT ENTSHA

Uma inkinga yenzeka uma usebenzisa i-filament endala noma eshibhile, zama i-spool ye-filament entsha nekhwalithi ephezulu ukuze ubone ukuthi inkinga iyahamba yini.

Izinkinga ze-Extruder

Izinkinga ze-Extruder zingabangela ngokuqondile i-extrusion engahambisani.Uma igiya lokushayela le-extruder lingakwazi ukubamba i-filament kanzima ngokwanele, i-filament ingase ishelele futhi inganyakazi njengoba kufanele.

Lungisa ukungezwani kwe-extruder

Bheka ukuthi i-extruder tensioner ixega kakhulu yini bese ulungisa i-tensioner ukuze uqiniseke ukuthi igiya lokushayela liwubamba ngokuqinile ngokwanele umcu.

HLOLA IGANI LE-DRIVE

Uma kungenxa yokuguga kwegiya lokushayela ukuthi i-filament ayikwazi ukubamba kahle, shintsha igiya elisha lokushayela.

Isikhathi sokuthumela: Dec-20-2020