GỊNỊ bụ Okwu ahụ?

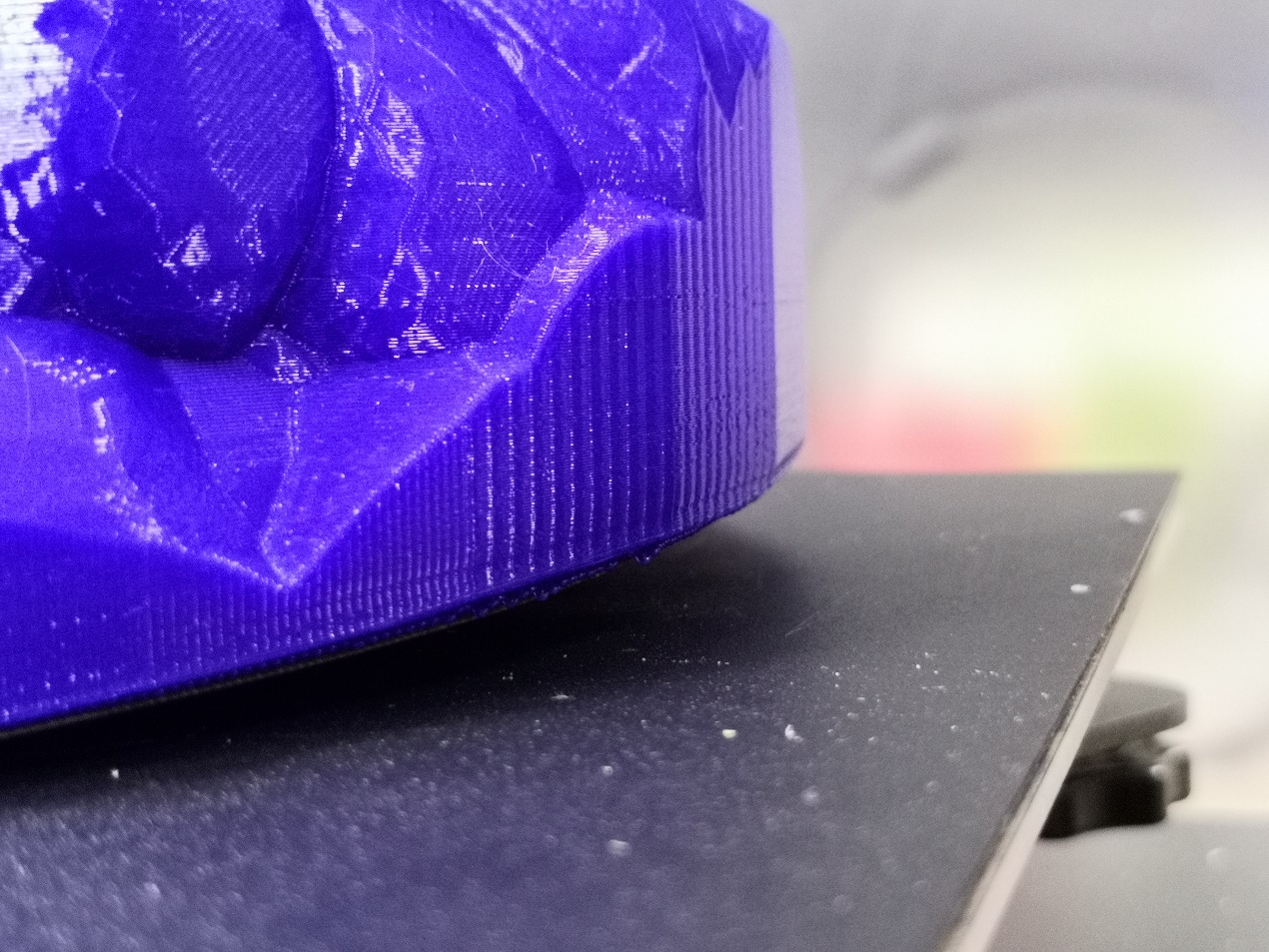

Ala ala ma ọ bụ elu elu nke ihe nlereanya ahụ na-agbagọ ma gbanwee n'oge mbipụta;ala agaghịkwa arapara na tebụl obibi akwụkwọ.Ngwunye a gbajiri agbaji nwekwara ike ime ka akụkụ elu nke ihe nlereanya ahụ gbajie, ma ọ bụ ihe nlereanya ahụ nwere ike kewapụ ya kpamkpam na tebụl nbipụta n'ihi nkwụsị na-adịghị mma na akwa obibi akwụkwọ.

Ihe kpatara ya

∙ Na-ajụ oyi ngwa ngwa

∙ Na-adịghị ike bonding elu

∙ Akwa Mbipụta nke Unlevel

NDỤMỌDỤ NDỊ MMADỤ NSOGBU

Na-ajụkwa oyi ngwa ngwa

Ihe ndị dị ka ABS ma ọ bụ PLA, nwere àgwà nke ịda mbà n'obi n'oge usoro ikpo ọkụ ka ọ dị jụụ na nke a bụ isi ihe kpatara nsogbu ahụ.Nsogbu nke ịgha agha ga-eme ma ọ bụrụ na filament jụrụ oyi ngwa ngwa.

Jiri ọkụ ọkụIhe ndina

Ụzọ kachasị mfe bụ iji akwa akwa na-ekpo ọkụ ma gbanwee okpomọkụ kwesịrị ekwesị iji mee ka ọ dị jụụ nke filament ma mee ka ọ dịkwuo mma na akwa obibi akwụkwọ.Ọnọdụ okpomọkụ nke akwa akwa na-ekpo ọkụ nwere ike na-ezo aka na akwadoro na ngwugwu filament.N'ozuzu, okpomọkụ nke akwa akwa PLA bụ 40-60 ° C, na okpomọkụ nke akwa akwa ABS bụ 70-100 ° C.

Gbanyụọ onye ofufe

N'ozuzu, ngwa nbipute na-eji fan mee ka filament extruded jụrụ oyi.Ịgbanye fan na mmalite nke mbipụta nwere ike ime ka filament dịkwuo mma na akwa obibi akwụkwọ.Site na sọftụwia slicing, enwere ike ịtọ ọsọ fan nke ọnụ ọgụgụ ụfọdụ n'ígwé dị na mmalite nke mbipụta ka ọ bụrụ 0.

Jiri ihe mkpuchi ọkụ

Maka ụfọdụ mbipụta buru ibu, ala nke ihe nlereanya ahụ nwere ike ịnọgide na-arapara n'àkwà na-ekpo ọkụ.Otú ọ dị, akụkụ elu nke elu ahụ ka nwere ike ịme nkwekọrịta n'ihi na ịdị elu dị oke ogologo iji mee ka okpomọkụ akwa akwa dị ọkụ ruo n'akụkụ elu.N'ọnọdụ a, ọ bụrụ na a na-ahapụ ya, tinye ihe nlereanya ahụ na mkpuchi nke nwere ike idobe mpaghara ahụ dum n'otu okpomọkụ, na-ebelata ọsọ ọsọ nke ihe nlereanya ahụ ma gbochie agha.

Elu njikọ na-adịghị ike

Adhesion na-adịghị mma nke kọntaktị dị n'etiti ihe nlereanya na akwa akwa nwere ike ime ka ọ dị egwu.Akwa obibi akwụkwọ kwesịrị inwe ụfọdụ udidi iji mee ka filament ahụ dịgidere nke ọma.Ọzọkwa, ala nke ihe nlereanya ahụ ga-adịrịrị nke ọma iji nwee njigide zuru oke.

Tinye ederede na akwa ebipụta

Ịgbakwunye ihe ederede n'àkwà ebipụta bụ ihe ngwọta a na-ahụkarị, dịka ọmụmaatụ ikpuchi teepu, teepu na-eguzogide okpomọkụ ma ọ bụ itinye obere osisi gluu, nke nwere ike ịsacha ngwa ngwa.Maka PLA, teepu mkpuchi ga-abụ ezigbo nhọrọ.

Hichaa akwa ebipụta

Ọ bụrụ na ihe ndina a na-ebipụta bụ nke iko ma ọ bụ ihe ndị yiri ya, griiz sitere na mkpịsị aka mkpịsị aka na nnukwu ụlọ nke nkwụnye glu nwere ike ime ka ọ ghara ịrapara.Na-ehicha ma dokwaa ihe ndina a na-ebipụta iji mee ka elu ya dị mma.

gbakwunye nkwado

Ọ bụrụ na ihe nlereanya ahụ nwere mgbagwoju anya ma ọ bụ njedebe dị mgbagwoju anya, jide n'aka na ị ga-agbakwunye nkwado iji jide ebipụta ọnụ n'oge usoro ahụ.Na nkwado ahụ nwekwara ike ịbawanye elu njikọ nke na-enyere aka ịrapagidesi ike.

gbakwunye brims na RAFTS

Ụfọdụ ụdị nwere naanị obere kọntaktị na-ebupụta akwa akwa ma dị mfe ịdapụ.Iji gbasaa elu kọntaktị, enwere ike ịgbakwunye Skirts, Brims na Rafts na ngwa nbicha.Skirt ma ọ bụ brims ga-agbakwunye otu oyi akwa nke ọnụọgụ ọnụọgụ nke ahịrị okirikiri na-apụta site na ebe mbipụta ahụ na-akpakọrịta na akwa ebipụta.Raft ga-agbakwunye ọkpụrụkpụ akọwapụtara na ala nke mbipụta ahụ, dịka ndò nke mbipụta ahụ.

Akwa Mbipụta Unlevel

Ọ bụrụ na edoghị akwa akwa ebipụta, ọ ga-ebute mbipụta na-enweghị isi.N'ọnọdụ ụfọdụ, nozzles dị oke elu, nke na-eme ka filament extruded ghara ịrapara n'àkwà ebipụta nke ọma, ma na-ebute agha.

Ọkwa akwa ebipụta

Onye nbipute ọ bụla nwere usoro dị iche iche maka nhazi ọkwa n'elu ikpo okwu, ụfọdụ dị ka Lulzbots ọhụrụ na-eji usoro nhazi akpaaka nke a pụrụ ịdabere na ya, ndị ọzọ dị ka Ultimaker nwere usoro nzọụkwụ site na nzọụkwụ na-eduzi gị site na nhazi nhazi.Rụtụ aka na ntuziaka ngwa nbipute gị maka otu esi edozi akwa ebipụta gị.

Oge nzipu: Dec-23-2020