WHAT’S THE ISSUE?

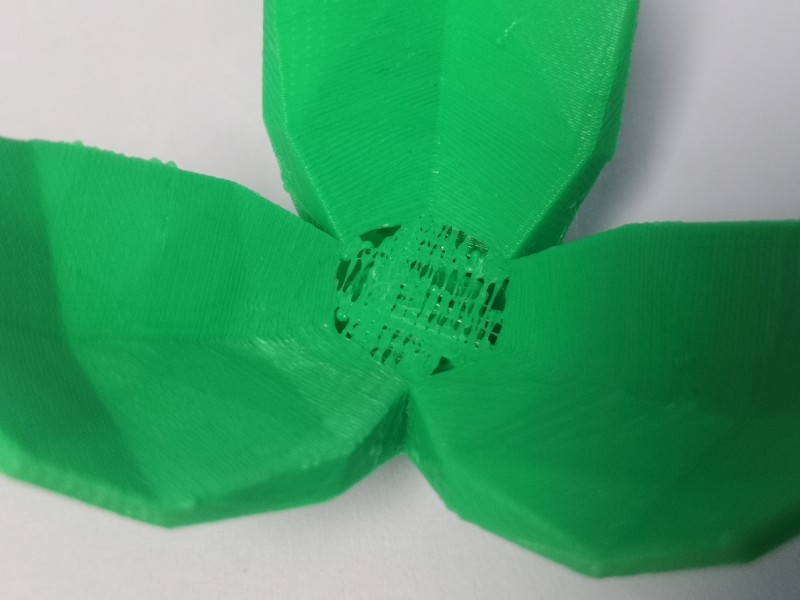

For models with a flat top layer, it is a common problem that there is a hole on the top layer, and there may also be uneven.

POSSIBLE CAUSES

∙ Poor Top Layer Supports

∙ Improper Cooling

TROUBLESHOOTING TIPS

Poor Top Layer Supports

One of the major reasons for pillowing is the insufficient support of the top layers, which causes the filament on the top layer collapses and forms holes. Especially for flexible filament such as TPU, stronger support is needed to form a strong top layer. Top layer supports can be strengthened by adjusting the slice setting.

INCREASE TOP LAYER THICKNESS

The most direct way to have a good support on top is to increase the thickness of the top layers. Generally, top thickness setting can be found in the advance setting of shell thickness setting. The layer thickness needs to be set to a multiple of the layer height. Increase the top layer thickness to 5 times of the layer height. If the top layer is still not strong enough, just continue to increase. However, the thicker the top layer, the longer the printing time.

Increase INFILL density

Infill density can also increase the support of the top layers. When the infill density is low, the voids inside the model are relatively large, so the top layer may collapse. In this case, you can increase the density to 20%-30%. However, the higher infill density, the longer the printing time.

Improper Cooling

When the cooling is insufficient, the filament will solidify slowly and not easy to form a strong top layer.

Check the cooling fan

Enable cooling fan when slicing, so that the filament can cool down quickly and become solid. Pay attention that whether the wind from the fan blows toward the print model. Increasing the speed of the fan can also help filament cools down.

DECREASE printing speed

During printing layers of small size, decreasing printing speed can increase the cooling time of the previous layer. This can prevent the layer collapse due to the weight of the upper filament.

Increase the distance between nozzle and print bed

Increasing the distance between the nozzle and the print bed before the start of printing. It may reduce the heat transmission from the nozzle to the model, making the filament cool down easier.

Post time: Dec-26-2020