WHAT’S THE ISSUE?

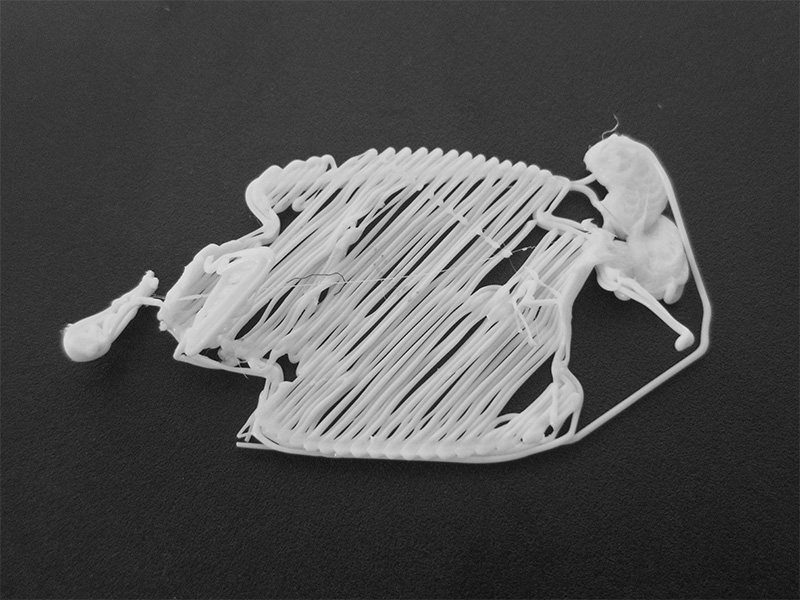

A 3D print should be sticked to the print bed while printing, or it would become a mess. The problem is common on the first layer, but still can happen in mid-print.

POSSIBLE CAUSES

∙ Nozzle Too High

∙ Unlevel Print Bed

∙ Weak Bonding Surface

∙ Print Too Fast

∙ Heated Bed Temperature Too High

∙ Old Filament

TROUBLESHOOTING TIPS

Nozzle Too High

If the nozzle is far away from the print bed at the beginning of the print, the first layer is hard to stick to the print bed, and would be dragged rather than pushed into the print bed.

ADJUST NOZZLE HEIGHT

Find the Z-axis offset option and make sure that the distance between the nozzle and the print bed is about 0.1 mm. Place a printing paper in between can help the calibration. If the printing paper can be moved but with slight resistance, then the distance is good. Be careful not to make the nozzle too close to the print bed, otherwise the filament would not come out from the nozzle or the nozzle would scrap the print bed.

ADJUST Z-AXIS SETTING IN THE SLICING SOFTWARE

Some slicing software like Simplify3D is able to set a Z-Axis global offset. A negative z-axis offset can make the nozzle closer to the print bed to the appropriate height. Be careful to only make small adjustments to this setting.

ADJUST PRINT BED HEIGHT

If the nozzle is at the lowest height but still not close enough to the print bed, try adjusting the height of the print bed.

Unlevel Print Bed

If the print be is unlevel, then for some parts of the print, the nozzle will not be close enough to the print bed that the filament will not stick.

LEVEL THE PRINT BED

Every printer has a different process for print platform leveling, some like the latest Lulzbots utilize an extremely reliable auto leveling system, others such as the Ultimaker have a handy step-by-step approach that guides you through the adjustment process. Refer to your printer’s manual for how to level your print bed.

Weak Bonding Surface

One common cause is simply that the print just can’t bond to the surface of the print bed. The filament needs a textured base in order to stick, and the bonding surface should be big enough.

ADD TEXTURE TO THE PRINT BED

Adding textured materials to the print bed is a common solution, for example masking tapes, heat resistant tapes or applying a thin layer of stick glue, which can be easily washed away. For PLA, masking tape will be a good choice.

CLEAN THE PRINT BED

If the print bed is made of glass or similar materials, the grease from fingerprints and the excessive build of glue deposits can all result in not sticking. Clean and maintain the print bed in order to keep the surface in good condition.

ADD SUPPORTS

If the model has complex overhangs or extremities, be sure to add supports to hold the print together during the process. And the supports can also increase the bonding surface that help sticking.

ADD BRIMS AND RAFTS

Some models have only small contact surfaces with the print bed and easy to fall off. To enlarge the contact surface, Skirts, Brims and Rafts can be added in the slicing software. Skirts or Brims will add a single layer of a specified number of perimeter lines radiating out from where the print makes contact with the print bed. Raft will add a specified thickness to the bottom of the print, according the shadow of the print.

Print Too Fast

If the first layer is printing too fast, the filament may not have time to cool down and stick to the print bed.

ADJUST PRINT SPEED

Slow down the print speed, especially when printing the first layer. Some slicing software like Simplify3D provides a setting for First Layer Speed.

Heated Bed Temperature Too High

High heated bed temperature can also make the filament hard to cool down and stick to the print bed.

LOWER BED TEMPERATURE

Try setting the bed temperature down slowly, by 5 degrees increments for instance, until it goes to a temperature balancing sticking and printing effects.

Old or Cheap Filament

Cheap filament may be made of recycle old filament. And old filament without an appropriate storage condition will age or degrade and become non-printable.

CHANGE NEW FILAMENT

If the print is using an old filament and the solution above is not working, try a new filament. Make sure the filaments are stored in a good environment.

Post time: Dec-19-2020