WHAT’S THE ISSUE?

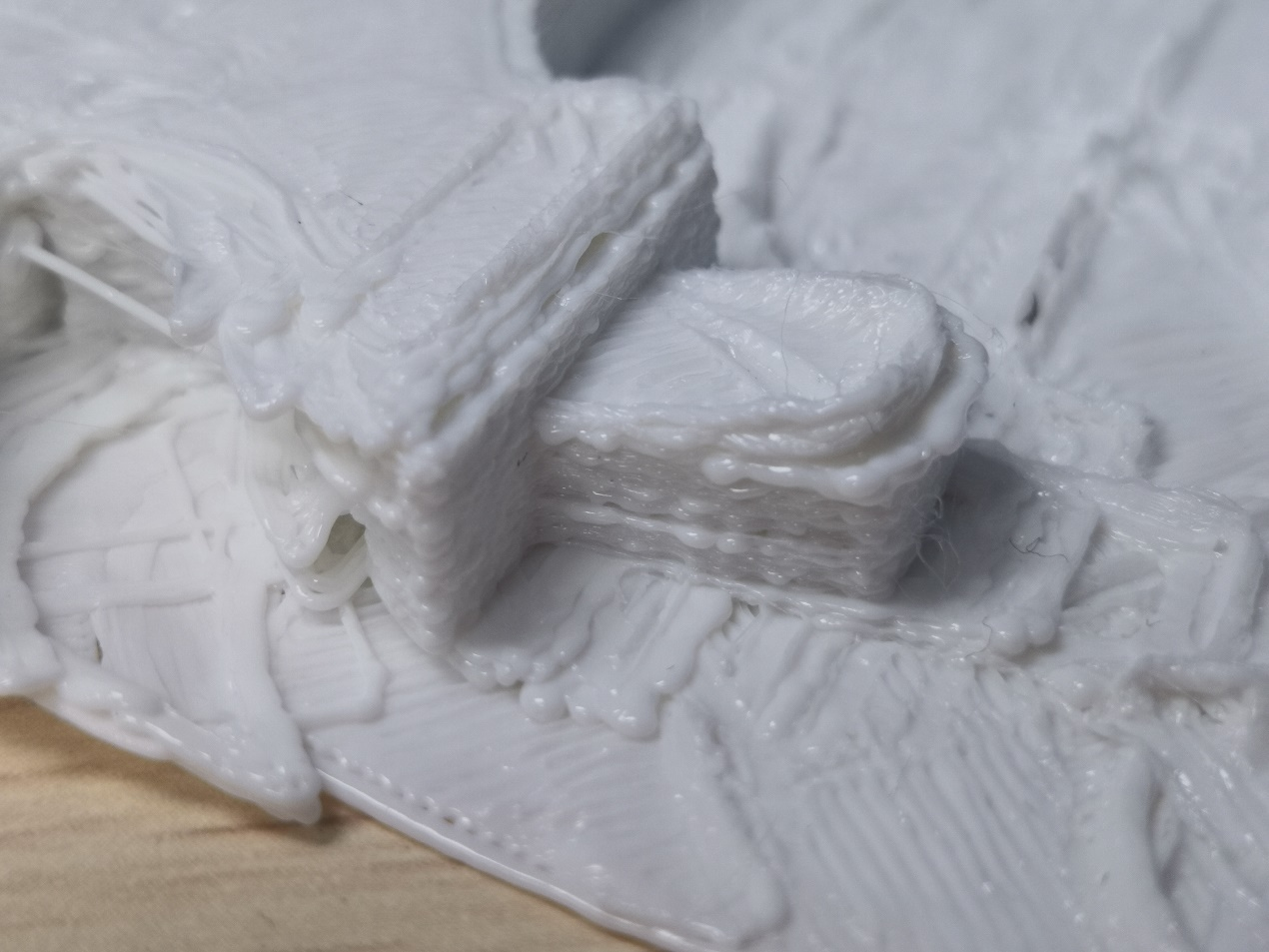

Over-extrusion means that the printer extrudes more filament than needed. This causes excess filament accumulate on the outside of the model which make the print in-refined and the surface is not smooth.

POSSIBLE CAUSES

∙ Nozzle Diameter Not Match

∙ Filament Diameter Not Match

∙ Extrusion Setting Not Good

TROUBLESHOOTING TIPS

Nozzle Diameter Not Match

If the slicing is set as the commonly nozzle used to 0.4mm diameter, but the printer has been replaced the nozzle with a smaller diameter, then it will cause over-extrusion.

Check the nozzle diameter

Check the nozzle diameter setting in the slicing software and the nozzle diameter on the printer, and make sure that they are the same.

Filament Diameter Not Match

If the diameter of the filament is larger than the setting in the slicing software, it will also cause over-extrusion.

CHECK THE FILAMENT DIAMETER

Check if the setting of filament diameter in the slicing software is the same as the filament you are using. You can find the diameter from the package or the specification of the filament.

MEASURE THE FILAMENT

The diameter of filament is commonly 1.75mm. But if the filament has larger diameter, it will cause over-extrusion. In this case, use a caliper to measure the diameter of the filament at a distance and several points, then use the average of the measurement results as the diameter value in the slicing software. It is recommended to use high precision filaments with standard diameter.

Extrusion Setting Not Good

If the extrusion multiplier such as flow rate and extrusion ratio in the slicing software are set too high, it will cause over-extrusion.

SET THE EXTRUSION MULTIPLIER

If the issue still exists, check the extrusion multiplier such as flow rate and extrusion ratio to see if the setting is low, usually the default is 100%. Gradually decrease the value, such as 5% each time to see if the problem is improved.

Post time: Dec-22-2020