WHAT’S THE ISSUE?

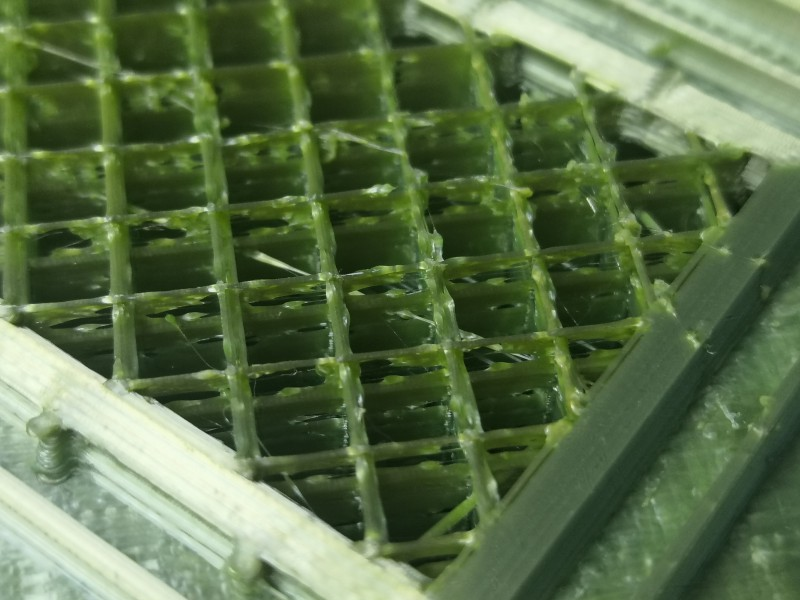

How to judge whether a print is good? The first thing that most people think of is to have a beautiful appearance. However, not only the appearance but also the quality of the infill is very important.

That is because the infill plays a critical part in the strength of the model. If the infill is not strong enough because of some defects, the model will be easily damaged by impact, and the appearance of the model will also be affected.

POSSIBLE CAUSES

∙ Incorrect Settings in Slicing Software

∙ Under-Extrusion

∙ Nozzle Jammed

TROUBLESHOOTING TIPS

Incorrect Settings in Slicing Software

The settings of the slicing software directly determine the infill style, density and printing method. If the settings are not proper, the model will not be strong enough due to poor infill.

CHECK THE inFILL DENSITY

Generally, an infill density of 20% should be used, and the strength will be weak if the infill density is lower. The larger the model, the greater the infill density is required to ensure the strength of the model.

DECREASE INFILL SPEED

Printing speed will affect the quality of printing. Generally speaking, lower printing speed will have better printing quality. Since the printing quality requirement of the infill is usually not as high as that of the outer wall, the infill printing speed can be higher. But if the infill printing speed is set too high, the strength of the infill will decrease. In this case, the infill strength can be improved by decreasing the infill printing speed.

CHANGE THE INFILL PATTERN

Most slicing software can set different infill patterns, such as grid, triangle, hexagon and so on. Different infill styles have different strength, so you can try changing the infill pattern to enhance infill strength.

Under-Extrusion

Under extrusion will also cause defects such as infill missing, poor bonding, reducing the strength of the model.

Go to Under-Extrusion section for more details of troubleshooting this issue.

Nozzle Jammed

If the nozzle is slightly jammed, it can also cause defects in the infill.

Go to Nozzle Jammed section for more details of troubleshooting this issue.

Post time: Dec-28-2020