MENENE MATSALAR?

Yadda za a yi hukunci ko bugu yana da kyau?Abu na farko da yawancin mutane ke tunanin shine samun kyakkyawan kamanni.Duk da haka, ba kawai bayyanar ba har ma da ingancin shigar yana da mahimmanci.

Wato saboda abun ciki yana taka muhimmiyar rawa a cikin ƙarfin samfurin.Idan shigarwar ba ta da ƙarfi sosai saboda wasu lahani, ƙirar za ta sami sauƙin lalacewa ta hanyar tasiri, kuma bayyanar ƙirar kuma za ta yi tasiri.

DALILAN DA AKE IYAWA

∙ Saitunan da ba daidai ba a cikin Software na Yankewa

∙ Ƙarƙashin Ƙarfafawa

∙ Nozzles Jammed

HANYOYIN MAGANCE MATSALAR

Saitunan da ba daidai ba a cikin Software na Yankewa

Saitunan software na yanka kai tsaye suna ƙayyade salo, yawa da hanyar bugu.Idan saitunan ba su dace ba, samfurin ba zai yi ƙarfi sosai ba saboda rashin cikawa.

DUBA YAWAN CIKA

Gabaɗaya, ya kamata a yi amfani da ƙarancin cika kashi 20%, kuma ƙarfin zai yi rauni idan ƙarancin cika ya ragu.Mafi girma samfurin, mafi girma yawan adadin da ake buƙata don tabbatar da ƙarfin samfurin.

RAGE CIN GUDU

Gudun bugawa zai shafi ingancin bugu.Gabaɗaya magana, ƙananan saurin bugu zai sami ingantaccen ingancin bugu.Tun da ingancin bugu na infill yawanci bai kai na bangon waje ba, saurin bugun bugu na iya zama mafi girma.Amma idan an saita saurin bugu na infill da yawa, ƙarfin shigarwar zai ragu.A wannan yanayin, ana iya inganta ƙarfin shigarwa ta rage saurin bugun shigar.

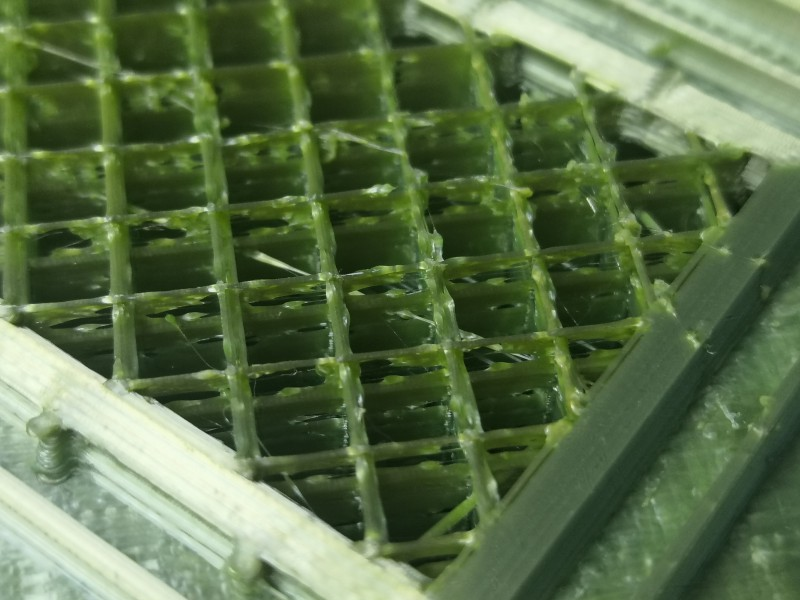

CANZA SIFFOFIN CIKI

Yawancin software na slicing na iya saita nau'ikan cika daban-daban, kamar grid, triangle, hexagon da sauransu.Salon shigarwa daban-daban suna da ƙarfi daban-daban, don haka kuna iya ƙoƙarin canza tsarin shigar don haɓaka ƙarfin shigarwa.

Ƙarƙashin fitarwa

Ƙarƙashin extrusion kuma zai haifar da lahani kamar rashin cikawa, rashin haɗin kai, rage ƙarfin samfurin.

Je zuwaƘarƙashin fitarwasashe don ƙarin cikakkun bayanai na magance wannan matsala.

Nozzle Jammed

Idan bututun ƙarfe ya ɗan matse shi, kuma yana iya haifar da lahani a cikin abin.

Je zuwaNozzle Jammedsashe don ƙarin cikakkun bayanai na magance wannan matsala.

Lokacin aikawa: Dec-28-2020