WHAT’S THE ISSUE?

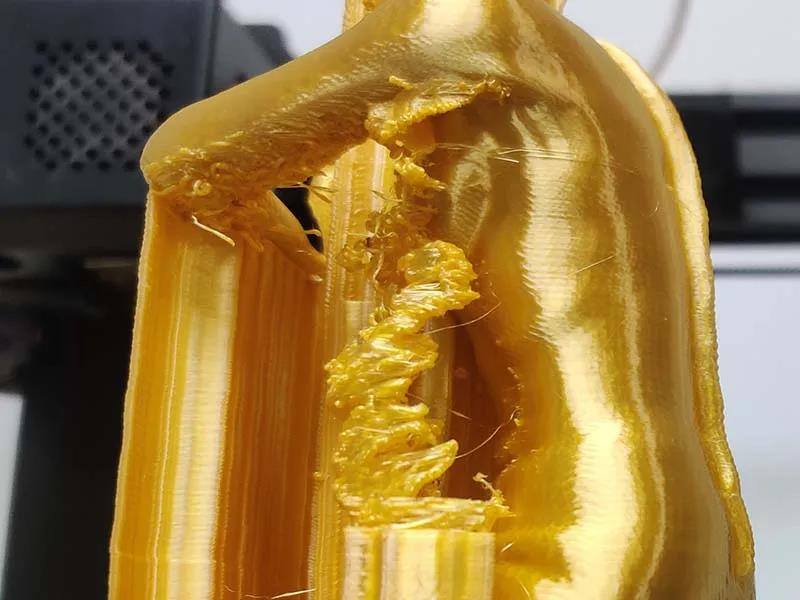

When doing a print that need to add some support, if the support fails to print, the support structure will look deformed or have cracks, making the model unsupported.

POSSIBLE CAUSES

∙ Weak Supports

∙ Printer Shakes and Wobble

∙ Old or Cheap Filament

TROUBLESHOOTING TIPS

Weak Supports

In some slicing software, there are multiple types of support to choose. Different supports offer different strengths. When the same type of the support is used on different models, the effect may be good, but may be bad.

SELECT THE CORRECT SUPPORTS

Do a survey for the model you are going to print. If the overhangs parts connect to section of the model which contact with the print bed well, then you can try using lines or zig zag supports. On the contrary, if the model has less contact on the bed, you may need stronger support like grid or triangle supports.

ADD PLATFORM ADHESION

Add platform adhesion such as a brim can increase the contact area between the support and print bed. In this situation, the support can be bond on the bed stronger.

INCREASE THE SUPPORT DENSITY

If the above 2 tips don’t work, try increasing the support density. The larger density can provide stronger structure which will not be affected by printing. Only one thing needs to concern is that the support is more difficult to remove.

CREATE IN-MODEL SUPPORTS

The support will be weak when they are overly tall. Especially the support area is small. In this case, you can create a tall block below where the supports are required, this can avoid the support become weak. Also, the support can own a solid base.

Printer Shakes and Wobble

Wobbling, shaking or impact of the printer will affect the printing quality badly. Layers may shift or lean, especially if the support only has a single wall thickness, and it is easy to fell apart when layers fail to bond together.

CHECK EVERYTHING IS TIGHT

If the shakes and wobble exceed the normal range, you should give the printer a check. Make sure all screws and nuts is tighten and re-calibrate the printer.

Old or Cheap Filament

Old or cheap filament may be another cause of the collapsed support. If you miss the best time to use the filament, poor bonding, inconsistent extrusion and crisp may happen that resulting in poor support printing.

CHANGE FILAMENT

Filament will be brittle after expiry date, which can usually be reflect in the quality of support printing. Change a new spool of filament to see if the problem is improved.

Post time: Jan-03-2021