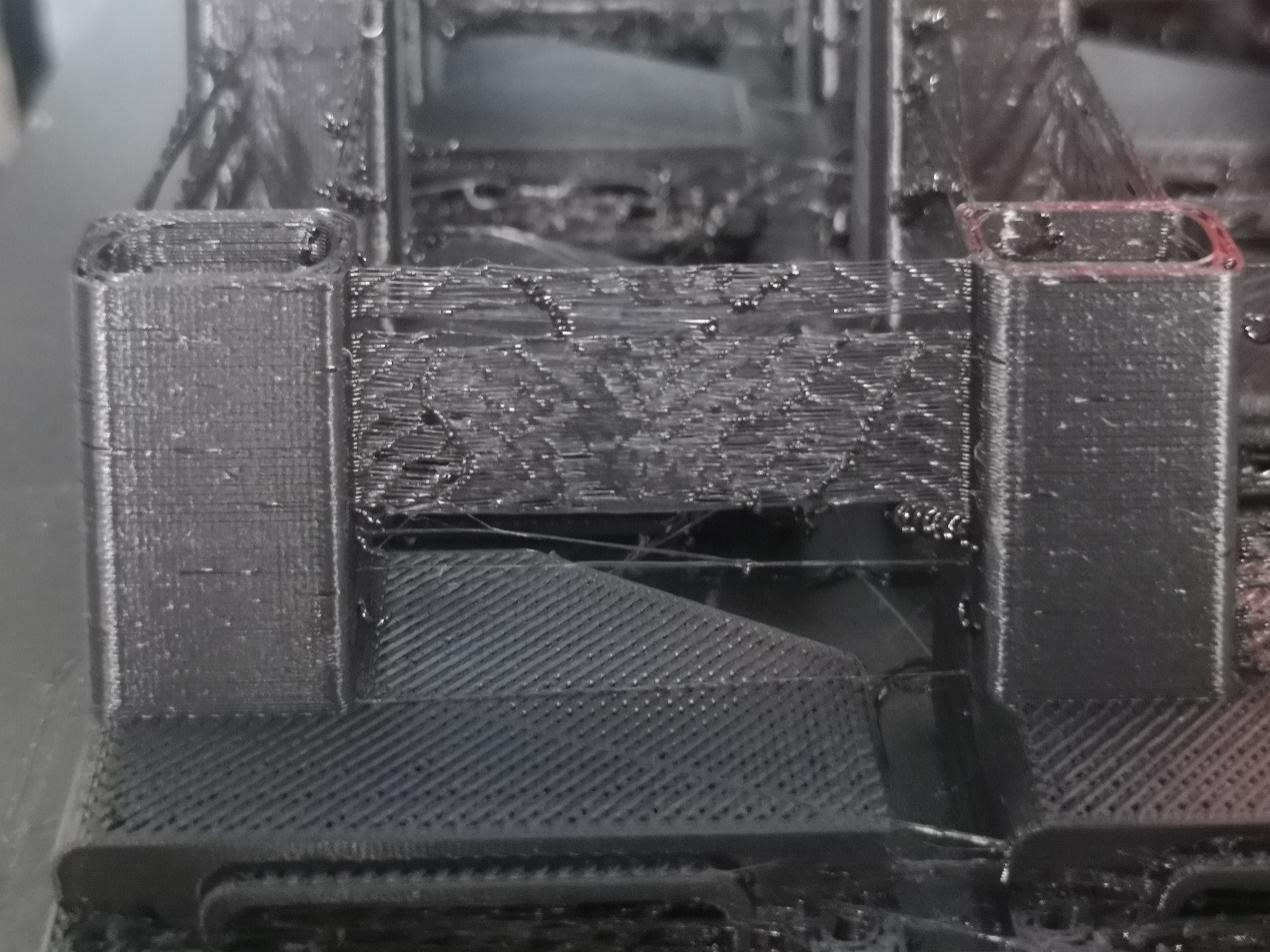

WHAT’S THE ISSUE?

When the nozzle moves over open areas between different printing parts, some filament oozes out and produces strings. Sometimes, the model will cover strings like a spider web.

POSSIBLE CAUSES

∙ Extrusion While Travel Move

∙ Nozzle Not Clean

∙ Filament Quility

TROUBLESHOOTING TIPS

Extrusion While Travel Move

After printing a part of the model, if the filament extrudes while the nozzle travel to another part, a string will be left over the travel area.

Setting RETRACTION

Most slicing softwares can enable retraction function, which will retract the filament before the nozzle travels over open areas to prevent the filament from extruding continually. In addition, you can also adjust distance and speed of retraction. Retraction distance determines how much the filament will be retracted from the nozzle. The more filament is retracted, the less likely the filament will be oozed. For a Bowden-Drive printer, the retraction distance needs to be set larger because of the long distance between the extruder and the nozzle. At the same time, the retraction speed determines how fast the filament is retracted from the nozzle. If the retraction is too slow, the filament may ooze from the nozzle and cause stringing. However, if the retraction speed is too fast, the rapid rotation of the feeding gear of the extruder may cause filament grinding.

MINIMUM TRAVEL

Long distance of nozzle traveling over open area is more likely lead to stringing. Some slicing softwares can set the minimum travel distance, reducing this value can make the travel distance as small as possible.

Decrease printing temperature

Higher printing temperature will make the filament flows easier, and also make it easier to ooze from the nozzle. Slightly decrease the printing temperature to make strings fewer.

Nozzle Not Clean

If there are impurities or dirt in the nozzle, it may weaken the effect of retraction or let the nozzle ooze a small amount of filament occasionally.

Clean the nozzle

If you find that the nozzle is dirty, you can clean the nozzle with a needle or use Cold Pull Cleaning. At the same time, keep the printer work in a clean environment to reduce dust entering the nozzle. Avoid using cheap filament that contains a lot of impurities.

Quality Problem of the Filament

Some filament is of poor quality so that they just easy to string.

CHANGE FILAMENT

If you have tried various methods and still have severe stringing, you can try to change a new spool of high-quality filament to see if the problem can be improved.

Post time: Dec-25-2020